After a year long apprenticeship about Lean and Six Sigma I can’t even go to a restaurant without thinking about how they can improve their processes by using improvement tools and approaches, it’s driving my wife crazy who is normally just trying to enjoy her food!

At work it has been better received, the most noticeable change is that in almost everything I am looking for ways to quantify the outputs of what I do by measuring something that matters to the people who matter – the patients (I work in a hospital). Here are just a few reasons to get into it.

Widely used in the NHS

Lean lingo and thinking is deeply embedded in many of the national programs that NHS Trusts are expected to participate, so it really pays dividends to understand this way of thinking even if you don’t necessarily agree with it. Here are some sites that I have found useful:

- NHS England » NHS IMPACT – Improving Patient Care Together – not just a clever acronym lots of nice case studies and tools here to use

- Getting It Right First Time – GIRFT

- NHS England » Patient safety

- Home page – Futures – not just Lean stuff a collaborative platform for people in the NHS

- NHS England – Model Hospital – great way to get benchmarks from similar institutions

- NHS Benchmarking Network

- About Q | Q Community

Become data driven

Lean is a great way to become more data driven with a large set of well used tools and a community of people to help you get the most out of them.

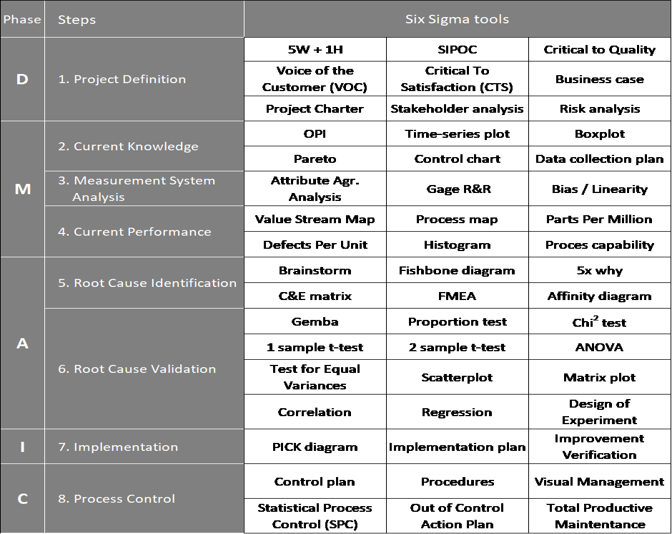

Here are just a few of the tools I used during my apprenticeship mapped to a commonly used improvement methodology (DMAIC)

You don’t have to use all of these tools or even the DMAIC methodology but selecting some meaningful tools in your context and weaving them into a coherent approach will radically improve the way your ideas for change are perceived and implemented. It helps you tell stories with data.

Communicate effectively

A lot of the artifacts generated by the tools above can be reused throughout the project to communicate what you are doing, how well you are doing it and how others can get involved to help you. Reusing the content means you can throw together presentations, justifications and communications quickly and consistently.

My favourite artifact is the A3 which refers to the size of paper it is traditionally put on but it can be done electronically too. It is a collection of reports that tell people exactly what, why and how your project is going. It can be used in standups, monthly meetings, updates to senior management and stuck on a wall with the team kanban and other reports. Mine generally look like this but it is the concept that is useful rather than the specific boxes.

Collaborate meaningfully

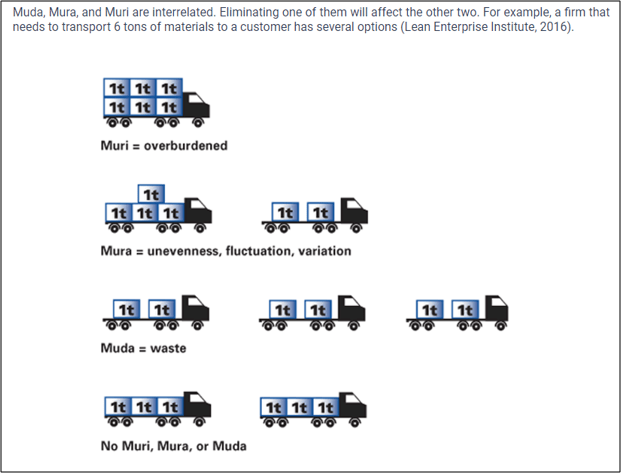

Everyone can find waste, variation and overburdening in their processes. Generally speaking, Lean focuses on waste while Six Sigma looks at variation. I have found the following illustration helpful for getting people to think about it.

Lean identifies eight common types of waste (TIMIWOOD is the acronym) listed below.

Lean is about creating value for the end users of a process by analysing the value streams and iterating towards perfection through improvements in Flow and Pull. Framing your improvement ideas and plans like this helps everyone collaborate more effectively.

Locking in the wins

There are lots of different approaches in Lean, Six Sigma and Improvement but all of them have an evaluation stage where you have a look at what you have done and either Adopt, Adapt or Abandon. If you are adopting then there is a focus on creating standard work through procedures and templates and setting up control measurement systems to make sure once the project is handed back to the business they can see if they are backsliding to previous bad habits.

I have really enjoyed the last year studying these concepts, it has radically changed the way I work making me a better data wrangler, communicator and collaborator. These approaches have enabled me to combat impostor syndrome, highest paid persons opinion bias and my own availability biases.

I no longer jump to a solution but consider a wide range of creative solutions generated by a groups of informed stakeholders. I now offer data as a service rather than a favour and I hope I have convinced you to do the same too.